CTD

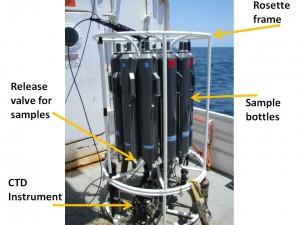

Water sampling off of a ship is a little more complex than merely dipping a YSI overboard and scooping up some water. The CTD is the device used to measure water chemistry as well as take samples for analysis. CTD stands for: Conductivity, Temperature, and Depth. The instrument itself is actually located on the base of the rosette stand, and as the water flows through it records the data and transmits it back to the ship’s lab. There, scientists can see the changes in the water column as the rosette is lowered to its destination. As the rosette returns to the surface, the members in the lab talk with the “doghouse,” where the crane operator works, to raise, slow, and stop its ascension. Once the rosette is stopped at the scientists’ desired depth, the sample bottles are closed, trapping the water at that precise level in the water column; the current readings from the CTD as well as time and location are recorded on a log in the lab. The process is repeated for as many stops between 1 and 24 depending on the size of the sample bottles and the scientists’ research focus.

Once back on deck, the rosette is secured and the sampling of the water can begin. Each of the large gray bottles is outfitted with a small white valve at its base. This allows for a sample to be taken in a controlled way. Gloves, sterilized and labeled bottles, sterile syringes, and team work are all required for maintaining the integrity of the samples. Depending on their purpose, the samples may be drawn into small bottles (some are even specific types of plastic and are sterilized a certain way, so as to not cross-contaminate with other elements, i.e. some plastics are made with aluminum and would then adulterate a sample with its presence), or into large gallon-sized containers. Some analysis can begin immediately on board, while other tests will be run once the samples are safely back to the lab. Until then, all samples will be kept in a controlled environment.

Recent Comments